This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

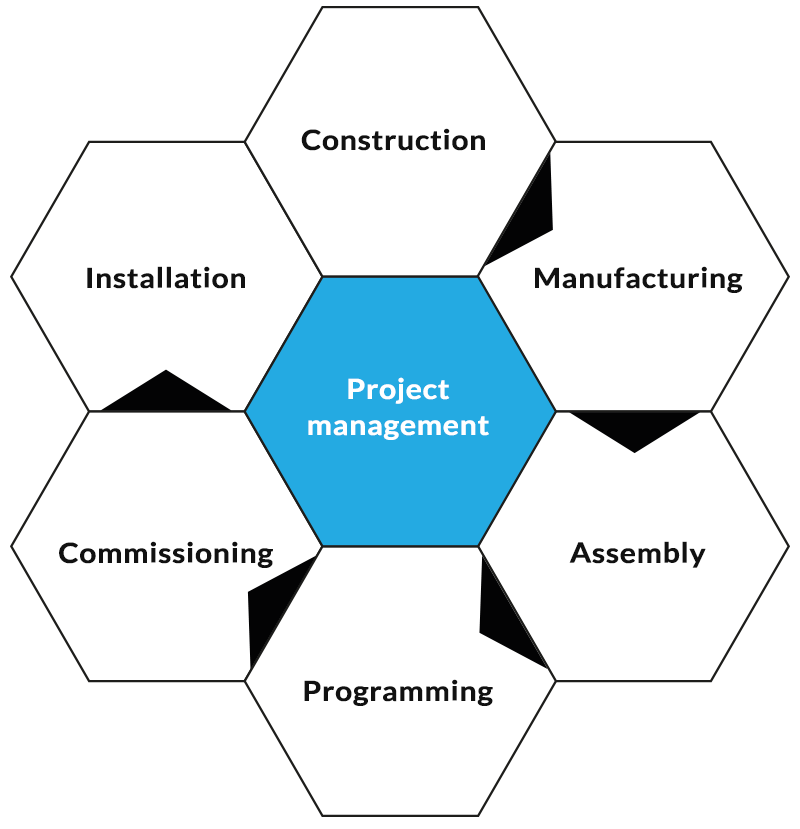

OUR PROCESS

At TM, the solutions emerge in a team thet sees the whole picture.

Project management.

We offer project management througout the project. Each project has its own project manager who has full control from the first request for quotation until the delivery is complete. We like to have close communication with our customers during the project and make frequent reconiliations.

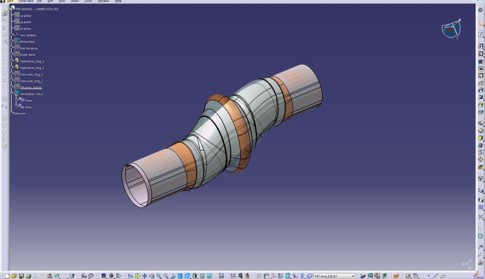

DESIGN

Mechanic, electric, pneumatic, hydraulic and simulation. We use Catia V5, Eplan P8 and Autocad. For forming simulation we use LS Dyna, and for robot we use Delmia and Motosim.

MANUFACTURING

Regarding the tools and machines you want, we handle the purchase of materials, processing, welding, surface treatment, polishing, assembly and adjustment.

Most things are solved in our own machines:

Milling (CNC 5-axia, CNC 3-axis). Turning machines. Welding MIG, MAG, TIG. grinding and laser cutting.

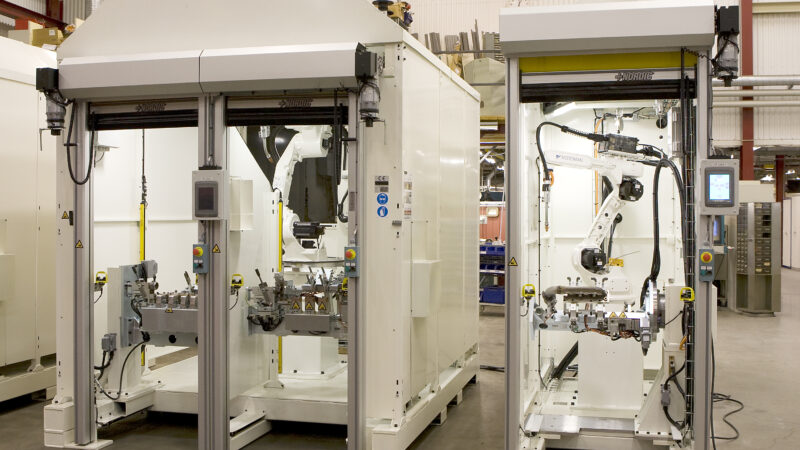

ASSEMBLY

All things we design and manufacture is assembled by our own staff in house.

Our assembly hall is about 1000m2. The design office is located next to the mounting hall.

Allt vi konstruerar och tillverkar monteras ihop av egen personal i huset med olika kompetenser. Vår monteringshall är ca 1000m2. Konstruktionskontoret ligger i anslutning till monteringshallen. This is perceived as smooth by our customers.

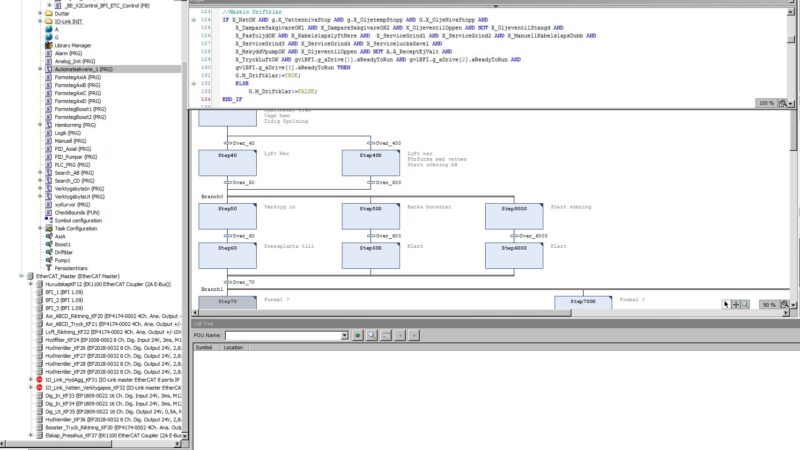

PROGRAMMING

We perform PLC programming, HMI programming, Robot programming.

Many of our equipment is delivered with remote connection via Cloud VPN.

We are familiar with many diferent PLC brands, such as:

Siemens, Allen Bradley, Mitsubishi, Codesys based systems.

COMMISSIONING

When the solution is built and programmed, we tune it and set cycle times, optimize, test e t c.

You as customer can approve everything before it is picked up and sent to you.

INSTALLATION

The equipment we deliver to you is installed by us and tested after installation. If the SAT is approved, the equipmentis then ready for production.