This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

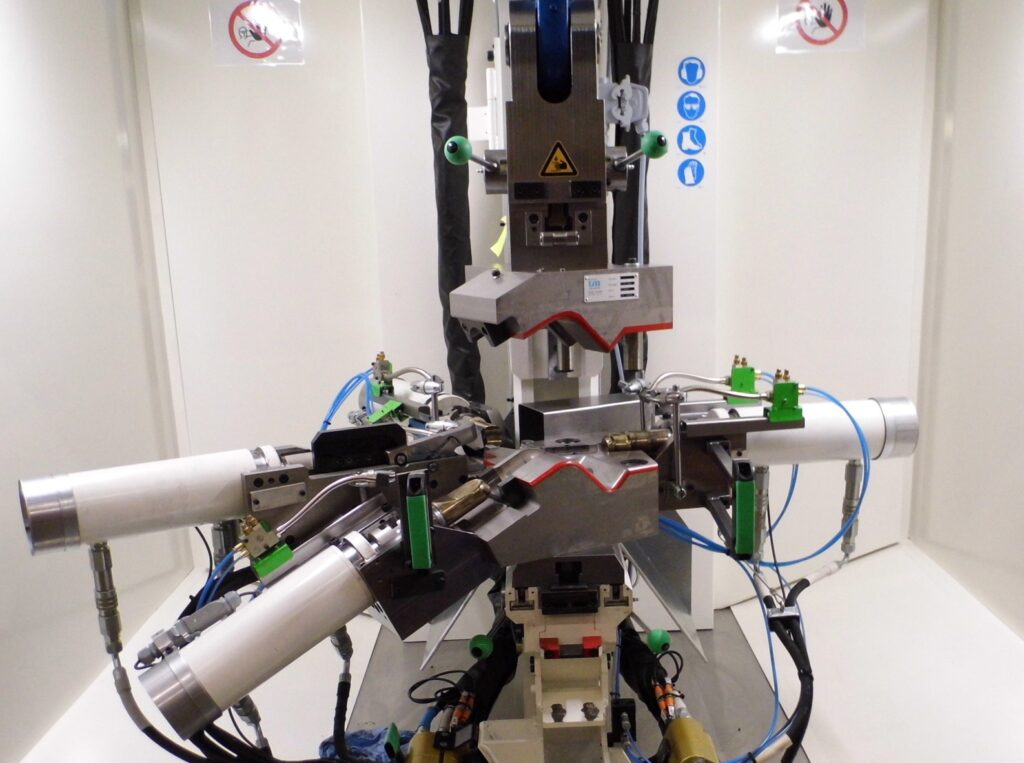

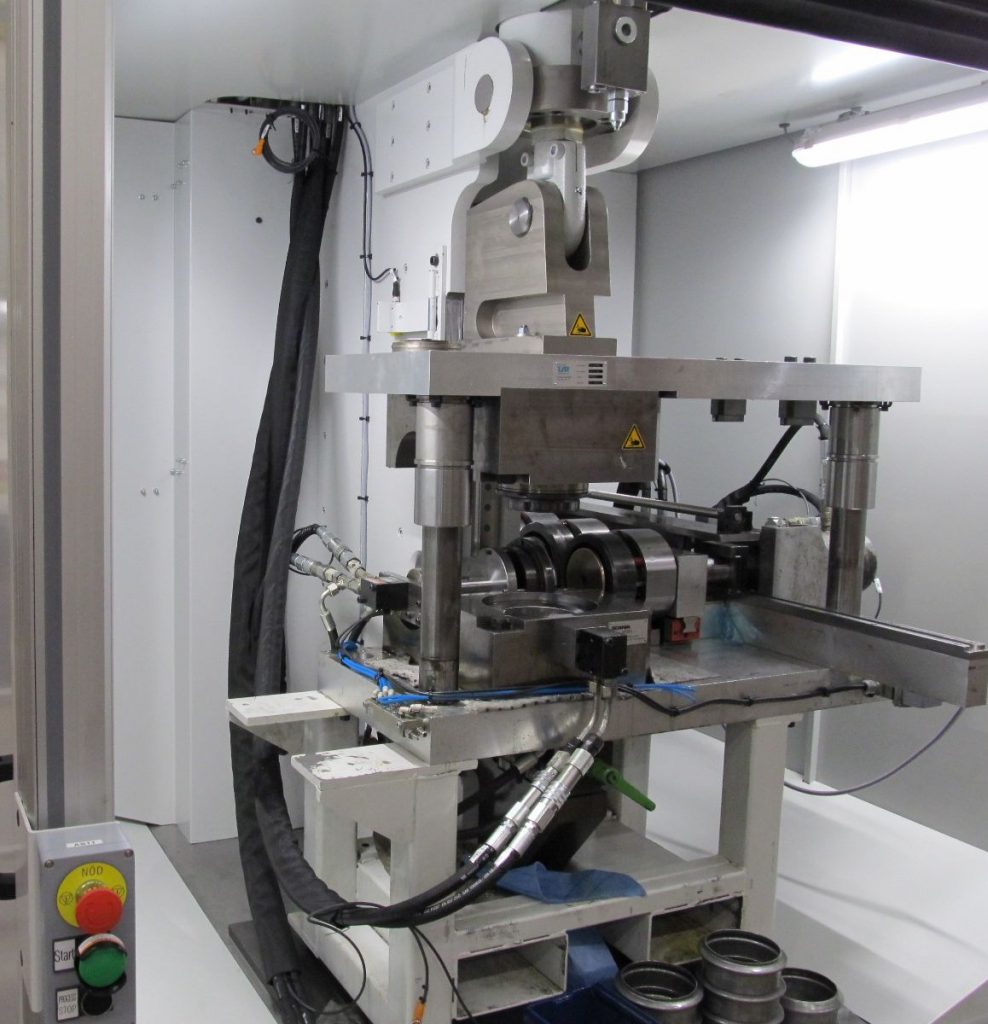

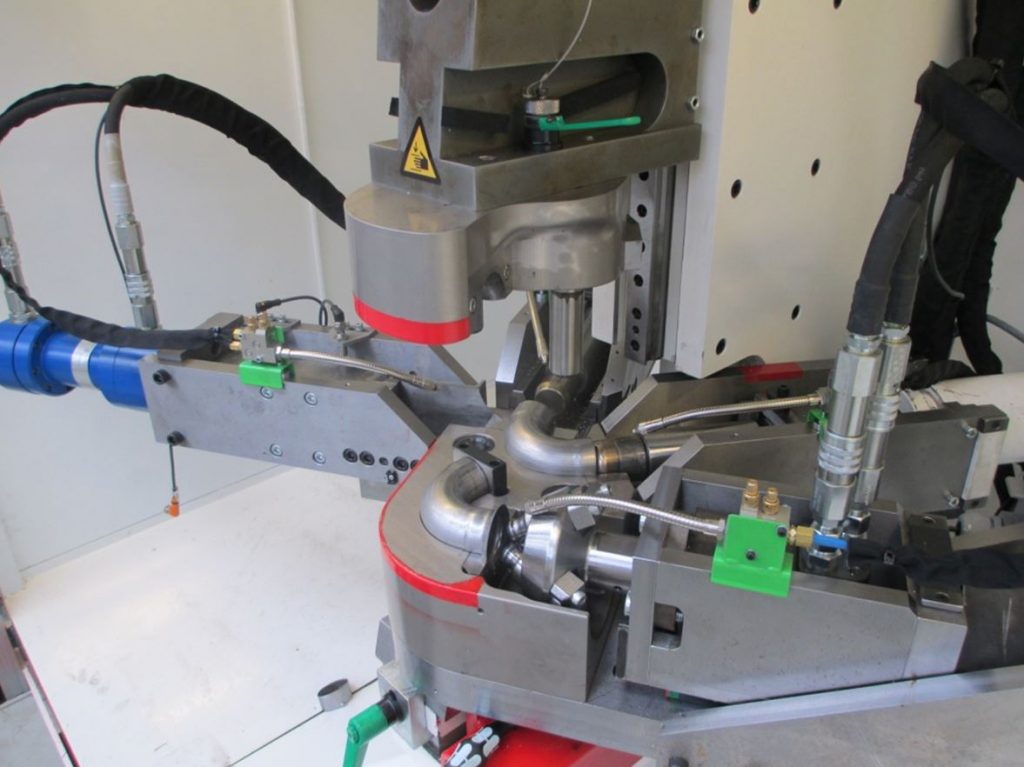

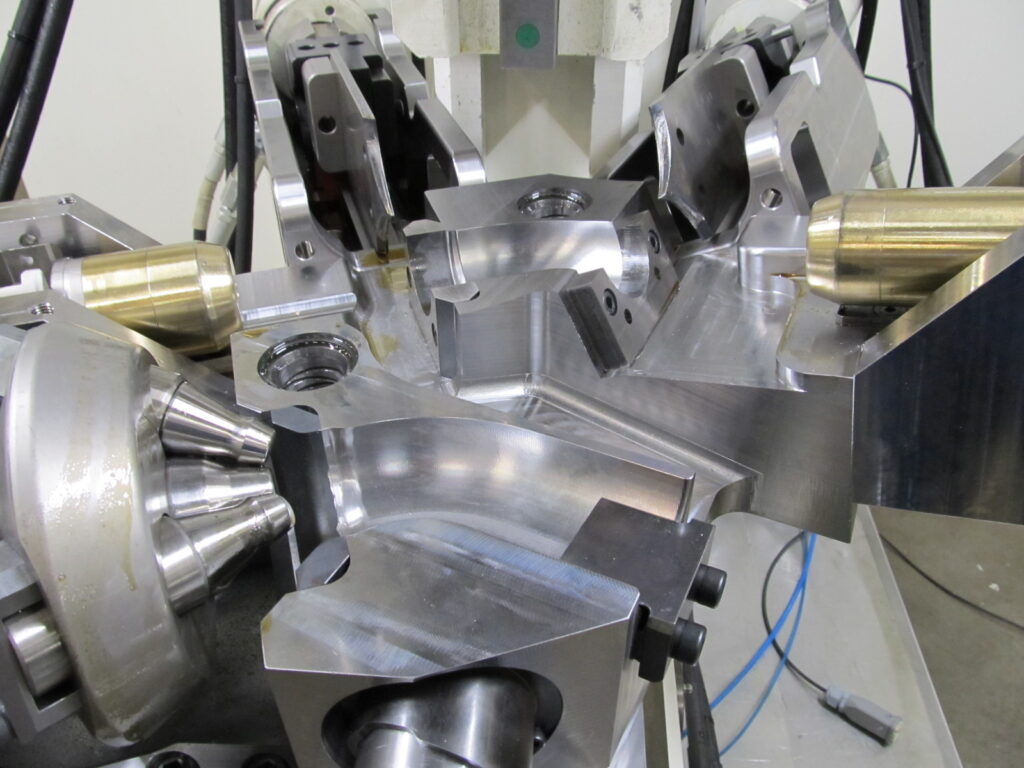

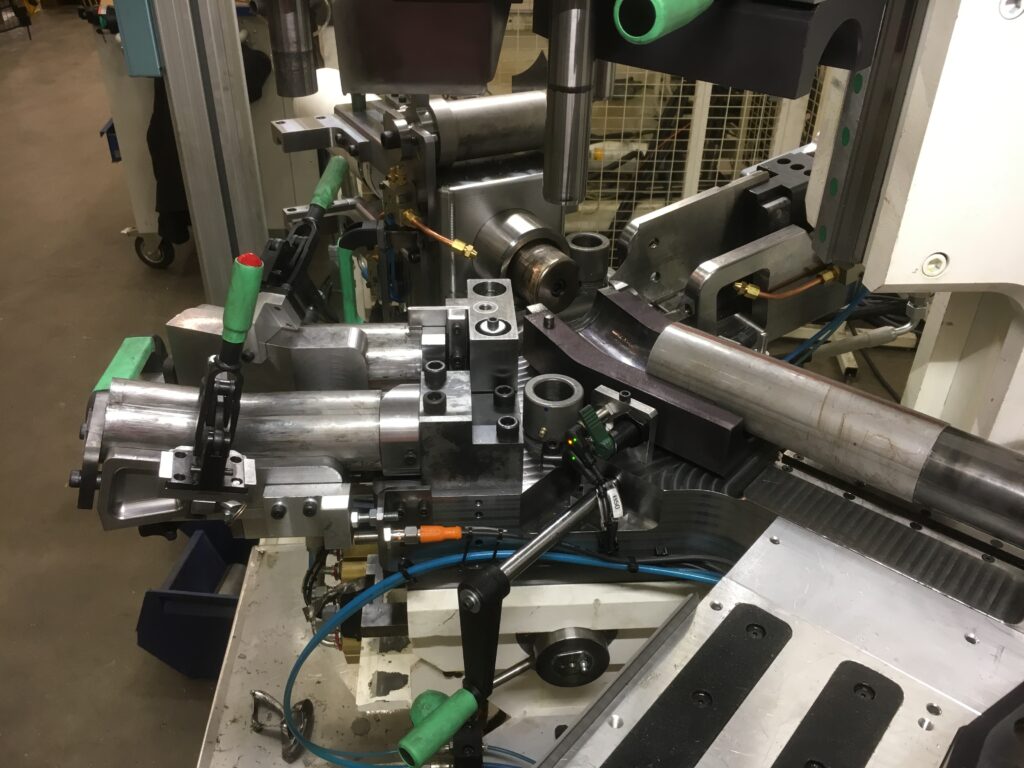

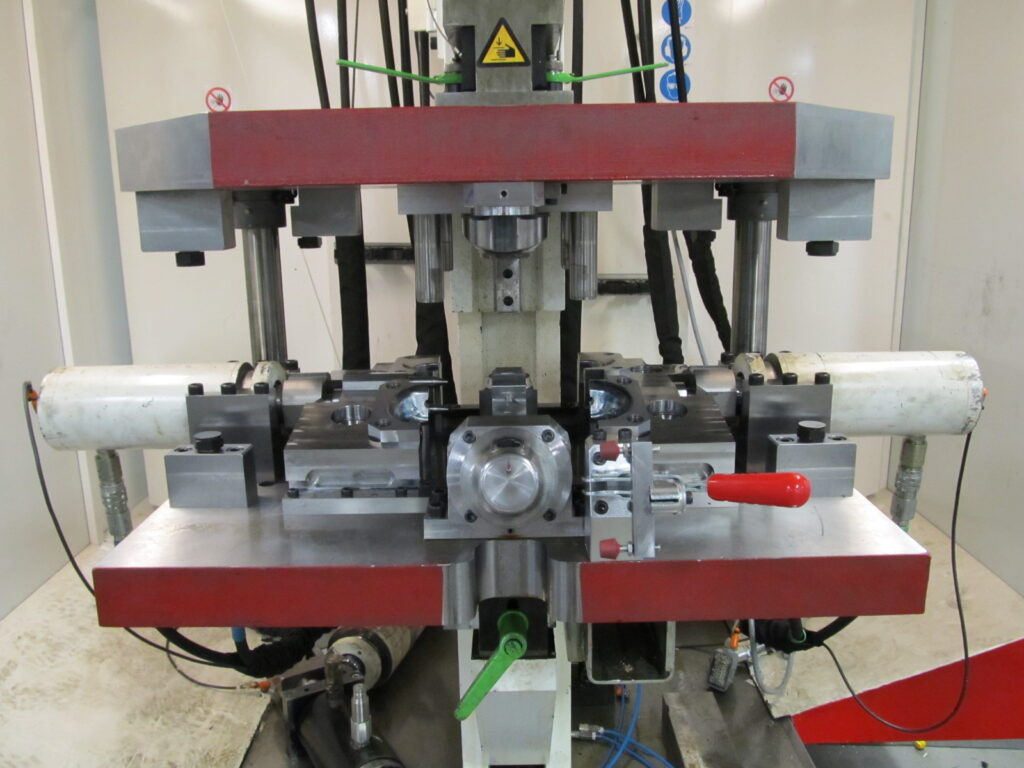

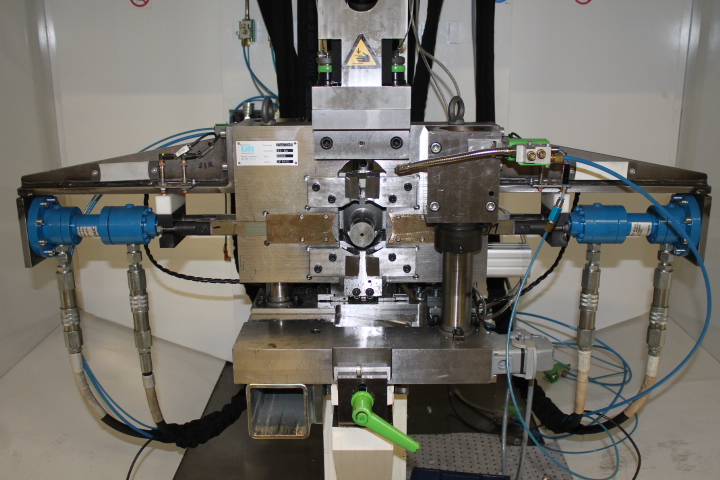

EFM End Forming Machine

Technical data (according to customer specification)

- 18,5 Kw frequency controlled hydraulics for higher performance, lower noice level lower energy consumption.

- Tool closing 10-30 ton (programmable in HMI Panel). Stroke 400mm.

- Possibility to place the hydraulic unit on top of machine for minimum usage of floor space.

- Up to 7 programmable tool movements.

- Sequence for all movements, positions etc. programmable in HMI panel..

- Proportional valves for all movements.

- Automatic tool lubrication. Programmable in HMI Panel.

- 4pct Option sensors (fe. part detection) programmed in HMI panel, when, if and how long time they should be active during the sequence.

- Typical cycle time 10-30 sec depending on application.

- Tool changeover require no tool.

- Tool changeover under 3 min.

- Frequency controlled high speed rolling door incl. light curtain.

- Recipe handling. Recipes can be exported/ Imported to USB stick.

- Prepared for robot handling.

- Remote accsess via Cloud VPN.

- Side doors for full acsess during tool change over and mainenance.

- We offer design and manufacturing of tools.

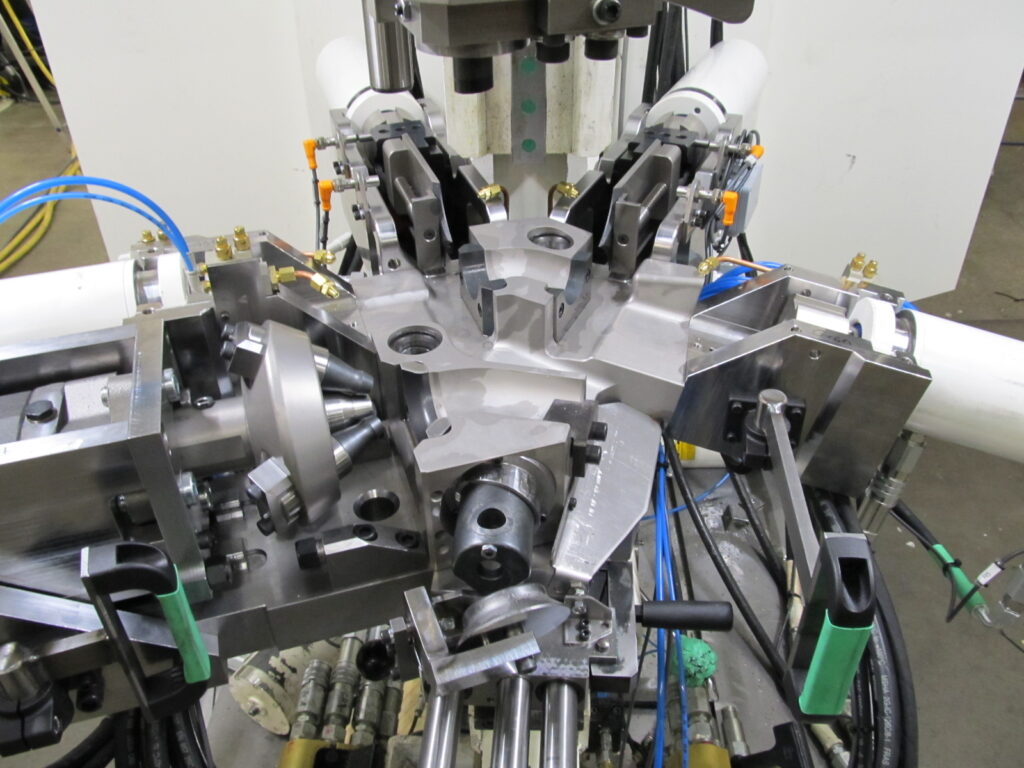

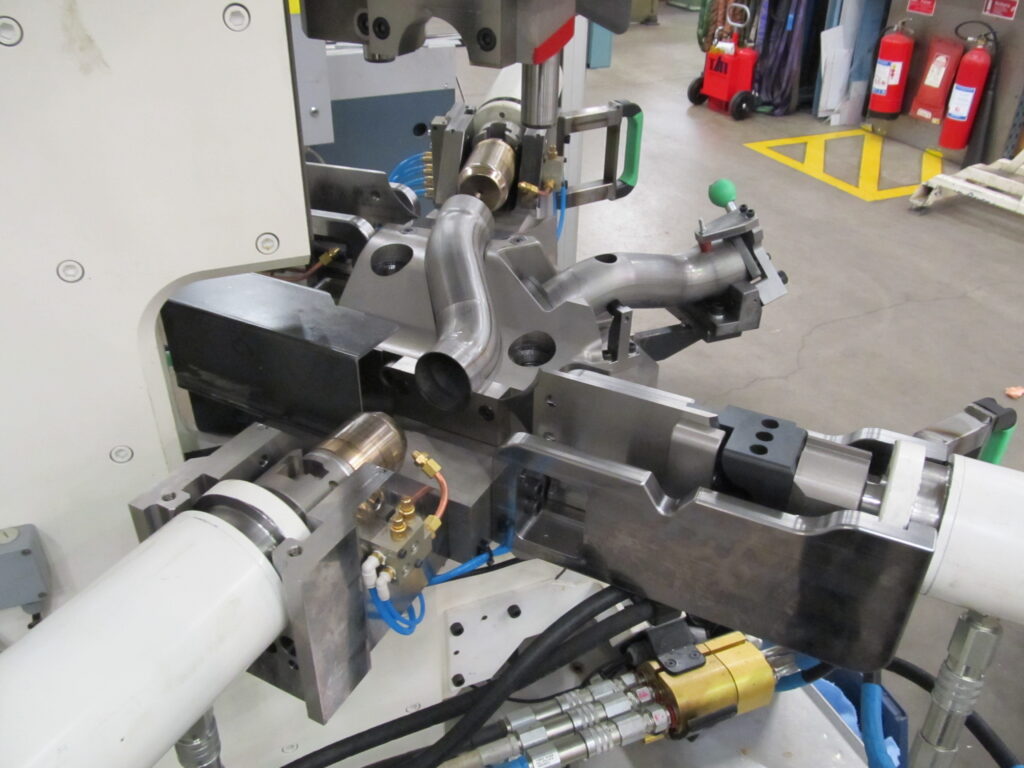

Example of tools

- Cutting

- Hole punching

- Formning

- Callibration

- Roll forming

- Push bending