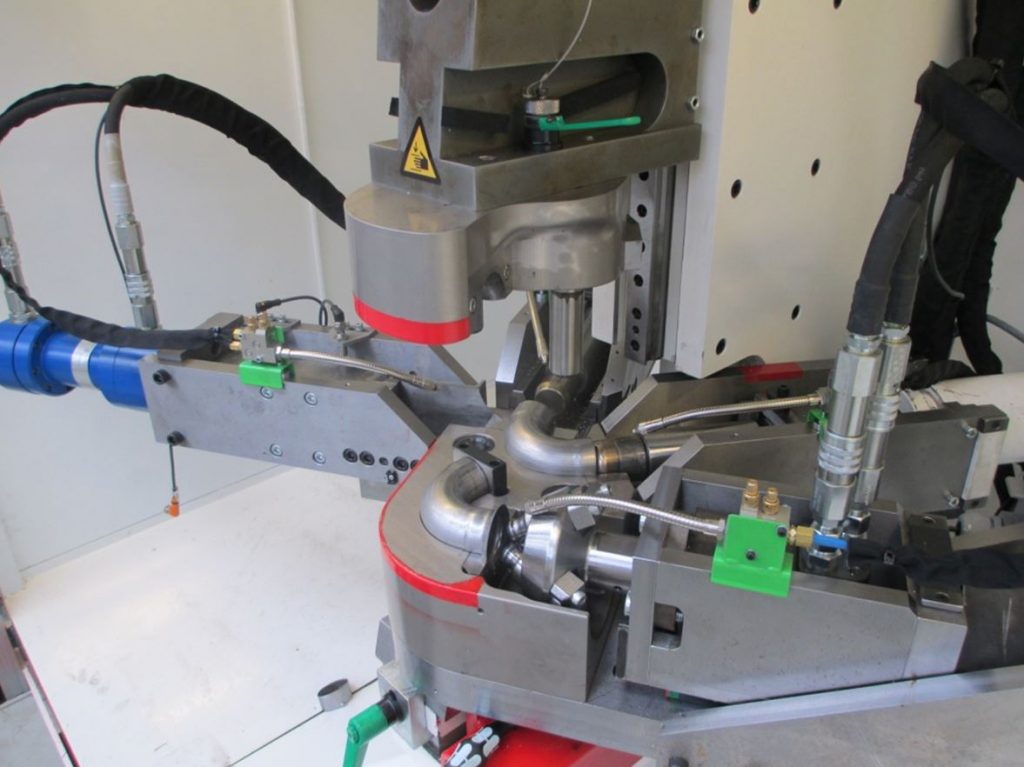

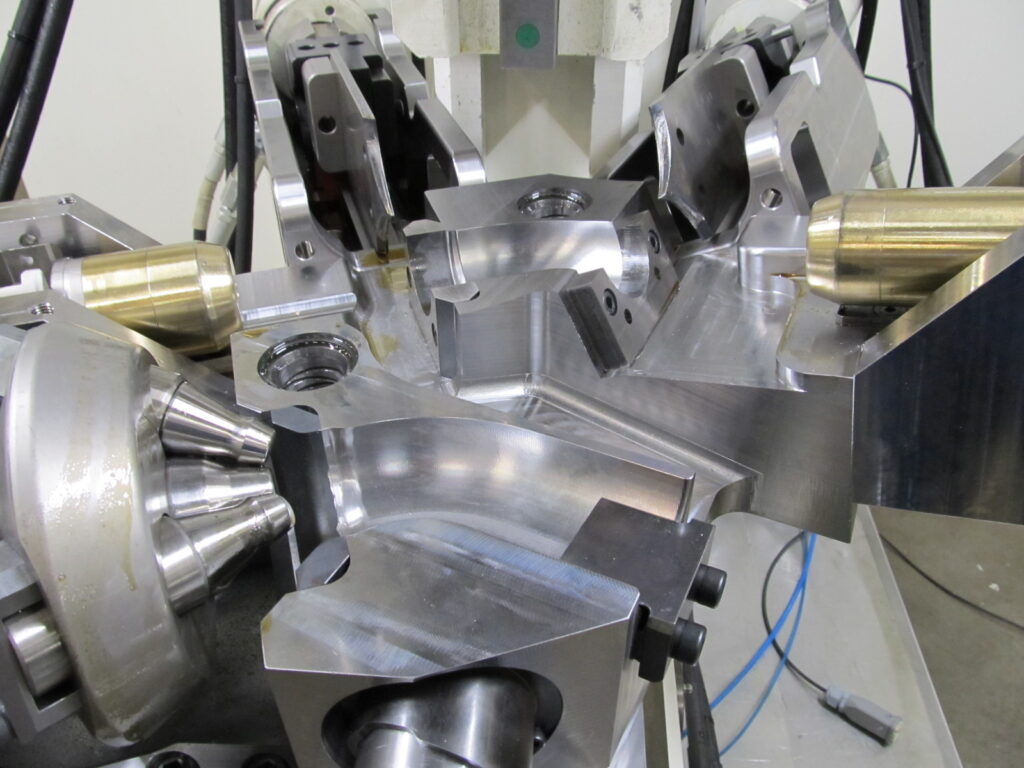

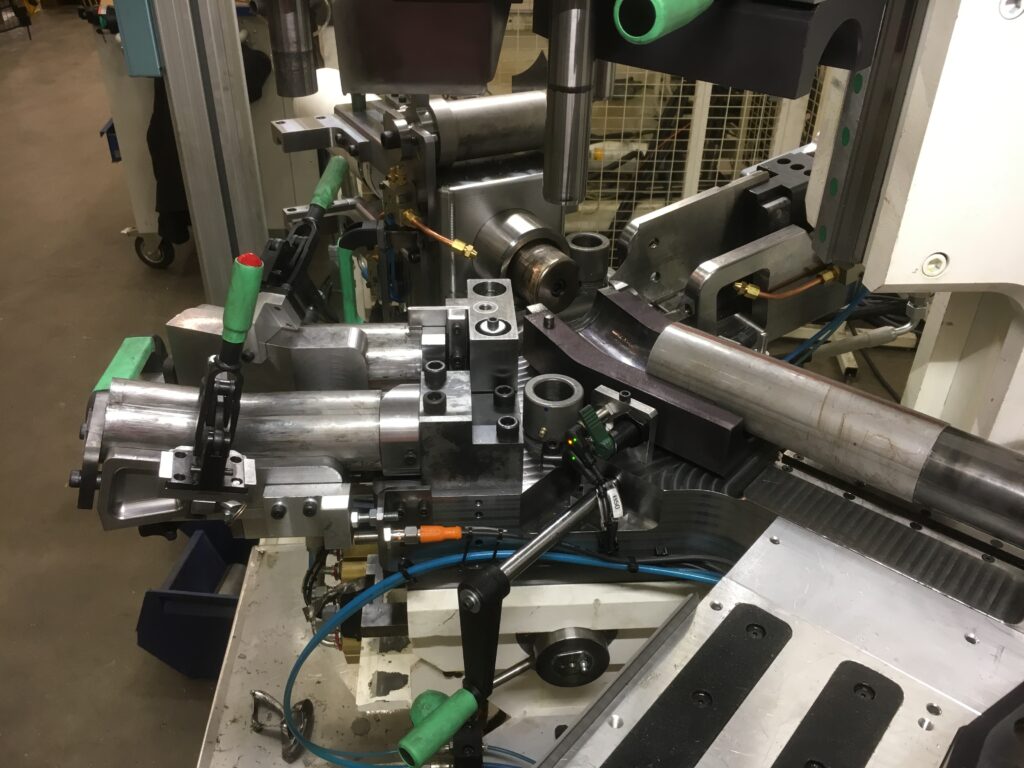

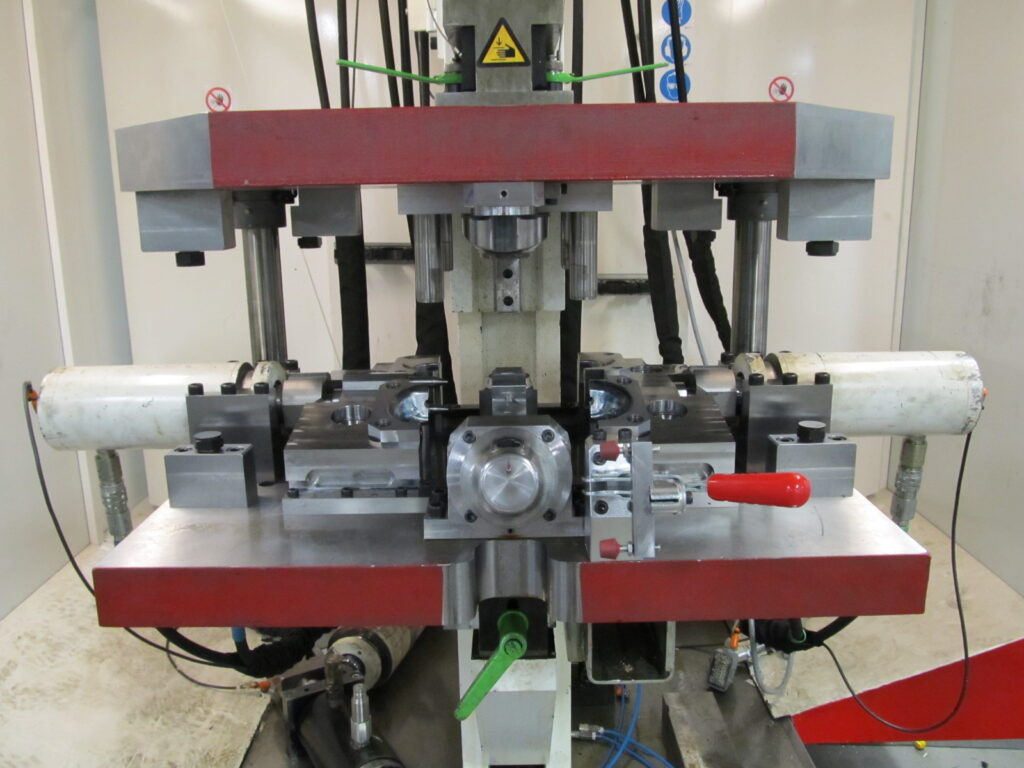

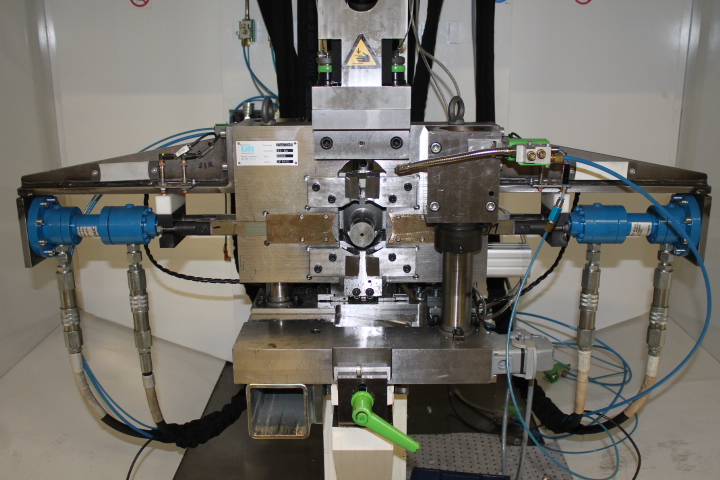

EFM End Forming Machine

Technical data (according to customer specification)

- 18,5 Kw frequency controlled hydraulics for higher performance, lower noice level lower energy consumption.

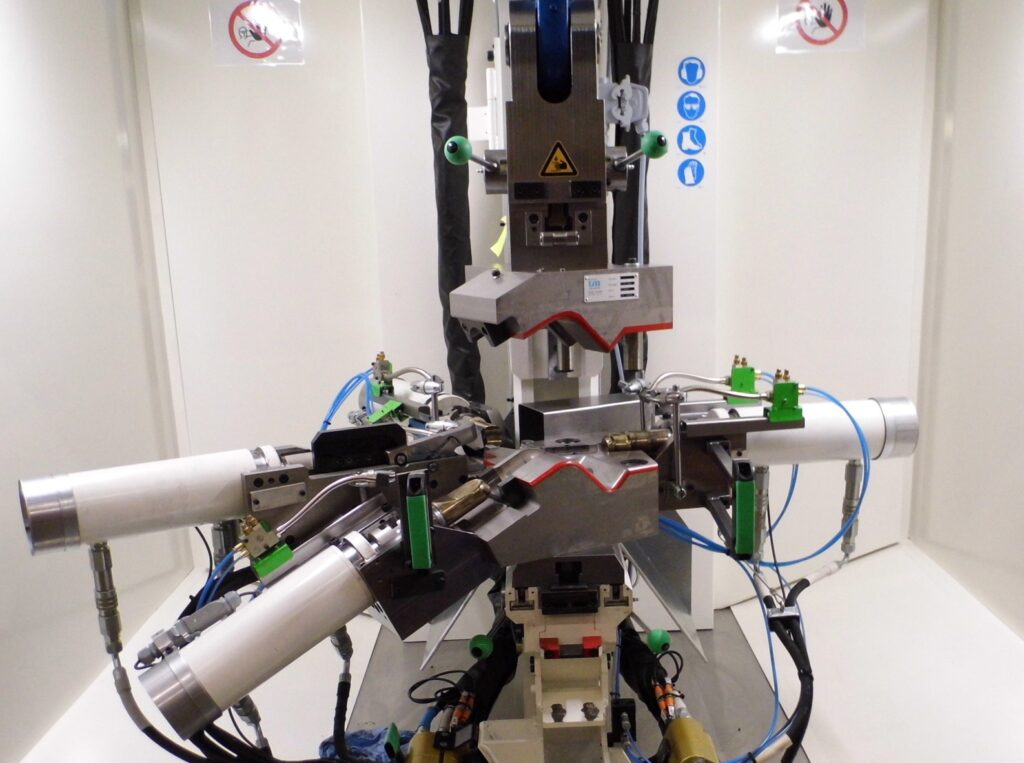

- Tool closing 10-30 ton (programmable in HMI Panel). Stroke 400mm.

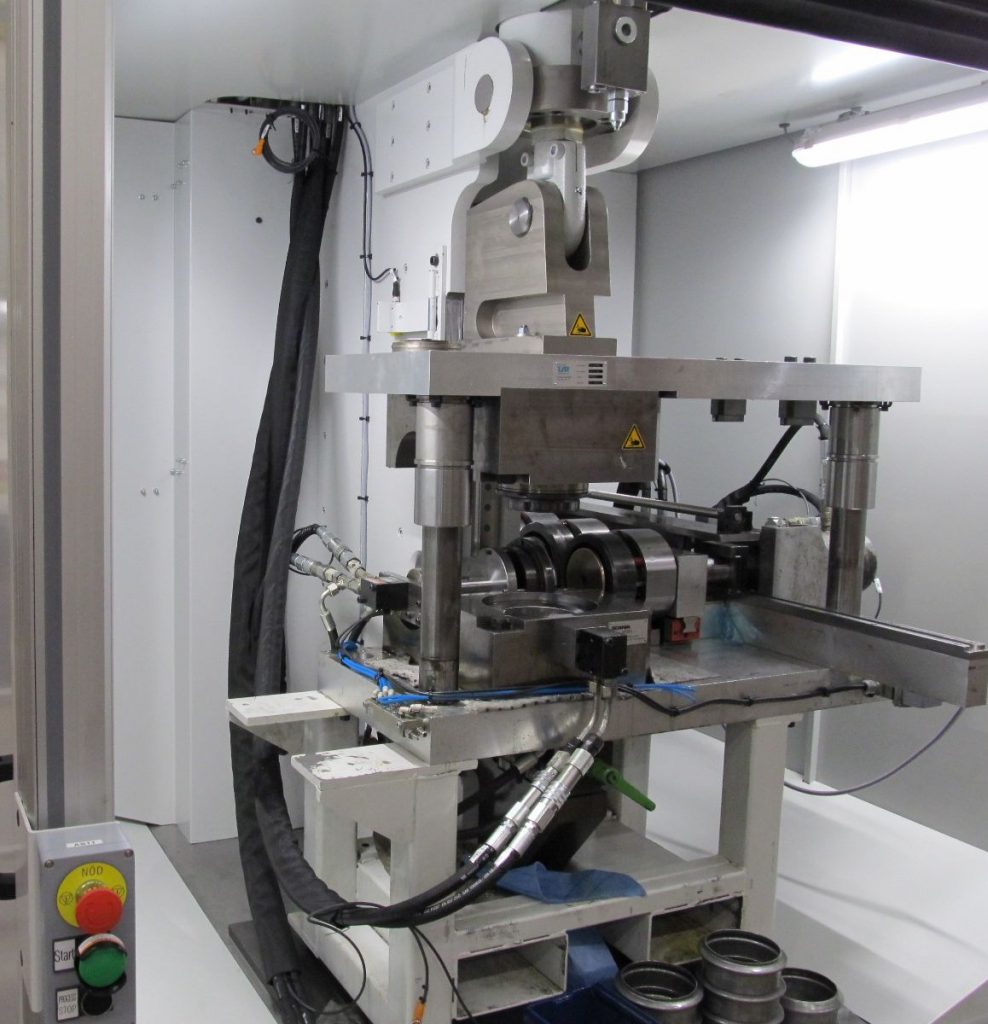

- Possibility to place the hydraulic unit on top of machine for minimum usage of floor space.

- Up to 7 programmable tool movements.

- Sequence for all movements, positions etc. programmable in HMI panel..

- Proportional valves for all movements.

- Automatic tool lubrication. Programmable in HMI Panel.

- 4pct Option sensors (fe. part detection) programmed in HMI panel, when, if and how long time they should be active during the sequence.

- Typical cycle time 10-30 sec depending on application.

- Tool changeover require no tool.

- Tool changeover under 3 min.

- Frequency controlled high speed rolling door incl. light curtain.

- Recipe handling. Recipes can be exported/ Imported to USB stick.

- Prepared for robot handling.

- Remote accsess via Cloud VPN.

- Side doors for full acsess during tool change over and mainenance.

- We offer design and manufacturing of tools.

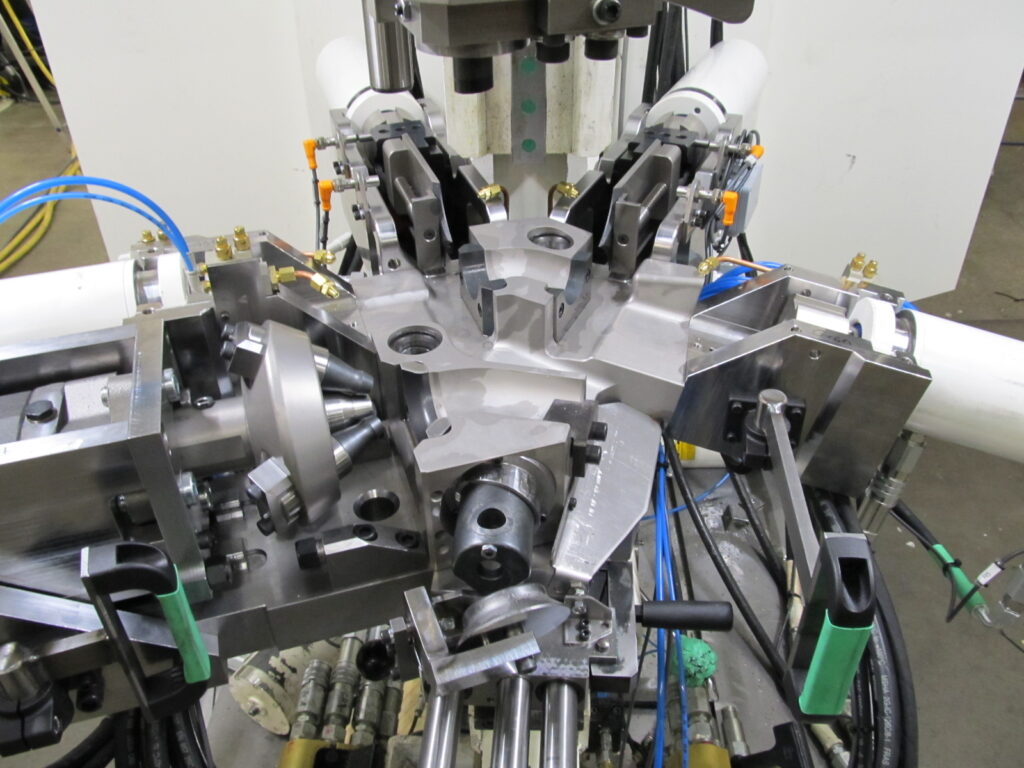

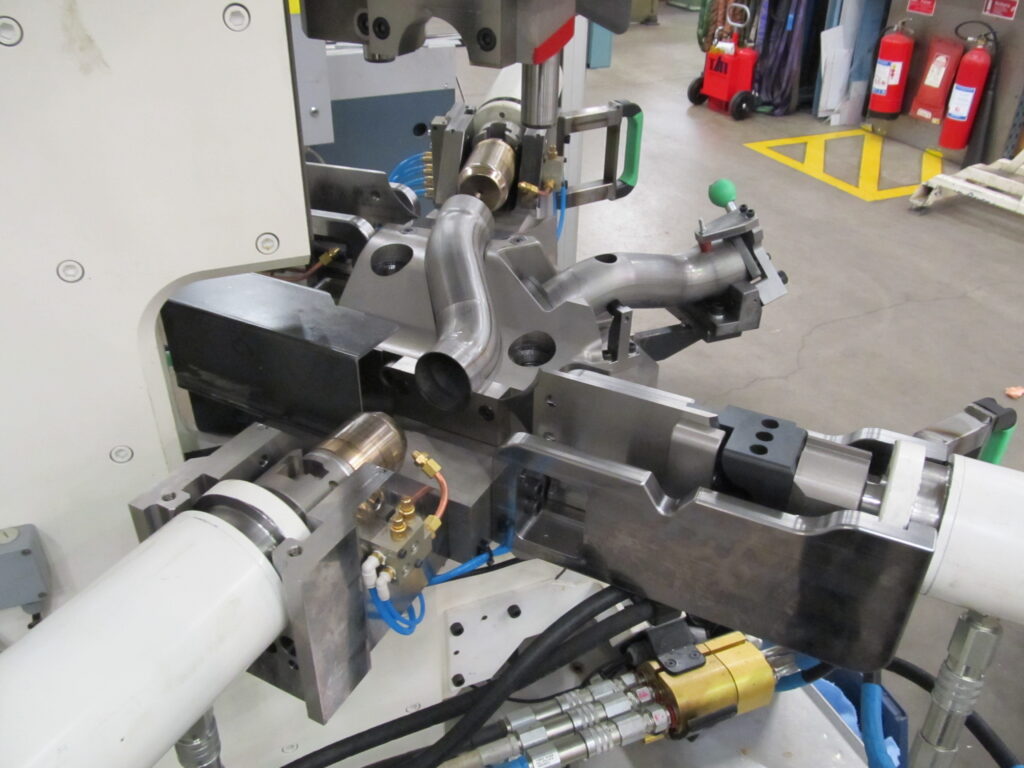

Example of tools

- Cutting

- Hole punching

- Formning

- Callibration

- Roll forming

- Push bending